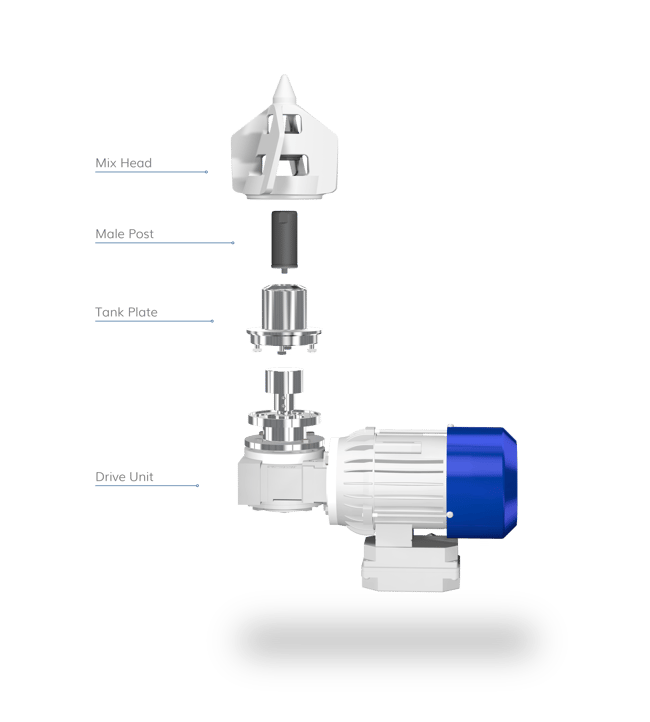

Metal-free design

Chemically stable with only pharmaceutical-grade plastic in product contact.

Service friendly

The bottom-mounted solution offers no need for headspace. The bearing is easily accessed and replaced, minimizing downtime during maintenance. Optimized for Cleaning In-Place (CIP).

Cost-efficient

A cost-efficient solution for aggressive chemicals and an attractive alternative to high alloys.