Compare our different evaluation services

Mixer Selector

SELECTION

Our Mixer Selector is available to you to on-demand, and around the clock. By entering which application and/or tank parameters, the selector will configure the input and suggest which mixer and mixer size that would be suitable for your project.

Application lab

VERIFICATION

During an application lab test we will be able to verify a process and result, and that the equipment and liquid material behave as intended. Participate either on-site in our lab, on a live digital link, or in a full video afterward – either way, you will be able to see the results for yourself.

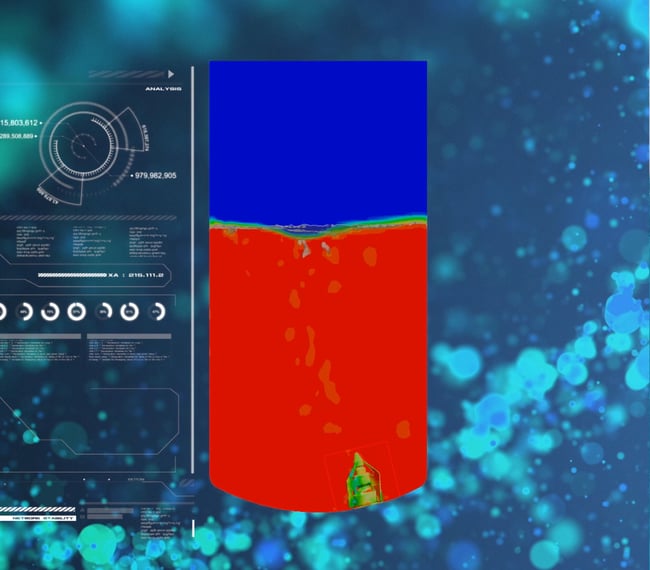

CFD analysis

SIMULATION

By performing a CFD analysis you will get a digital replica of the intended mixing process, with the correct vessel conditions, material viscosity, etc, and will get a full simulation insight on the performance.

6.jpg?width=650&name=workflow%20application%20lab%20(short%20version)6.jpg)