In recent years, bioreactors have emerged as revolutionary tools that are reshaping the landscape of both the pharmaceutical, and food industries. Devices originally developed for laboratory-scale experiments have now become vital components in large-scale production processes. The convergence of scientific advancements, technological innovations, and sustainability concerns has paved the way for bioreactors to take center stage.

Versatile vessel with a wide range of use

Bioreactors are versatile vessels designed to cultivate biological materials under controlled conditions, mimicking the natural environment required to grow cells, tissues, and microorganisms. This adaptability has led to their widespread adoption in various applications. A few examples of what can be produced using a bioreactor are bacterial cultures, mammalian cells, yeast cells, algae, and in recent years cultivated meat.

Mammalian cells and bacterial cultures are the most common in the medical industry and can be used to produce several pharmaceutical products, such as enzymes, antibodies, antibiotics, and vaccines.

Bioreactors are crucial in the production of vaccines, which can be produced using various cell cultures, including mammalian and insect cells. Some vaccines, like those against the flu and human papillomavirus (HPV), are produced using bioreactor systems. The cells are infected with a virus or a viral component, and the resulting proteins produced in the cell are harvested and purified to create the vaccine.

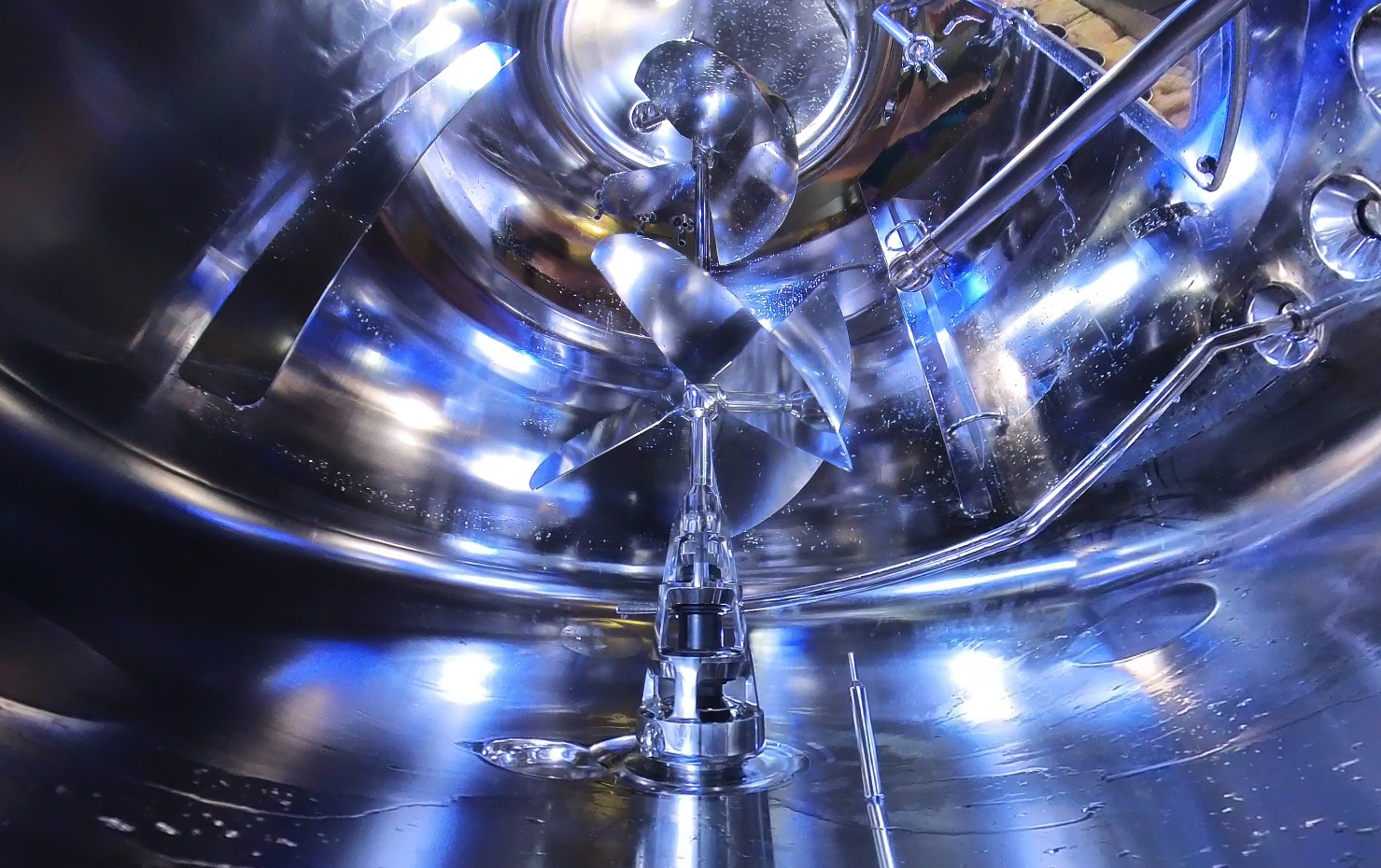

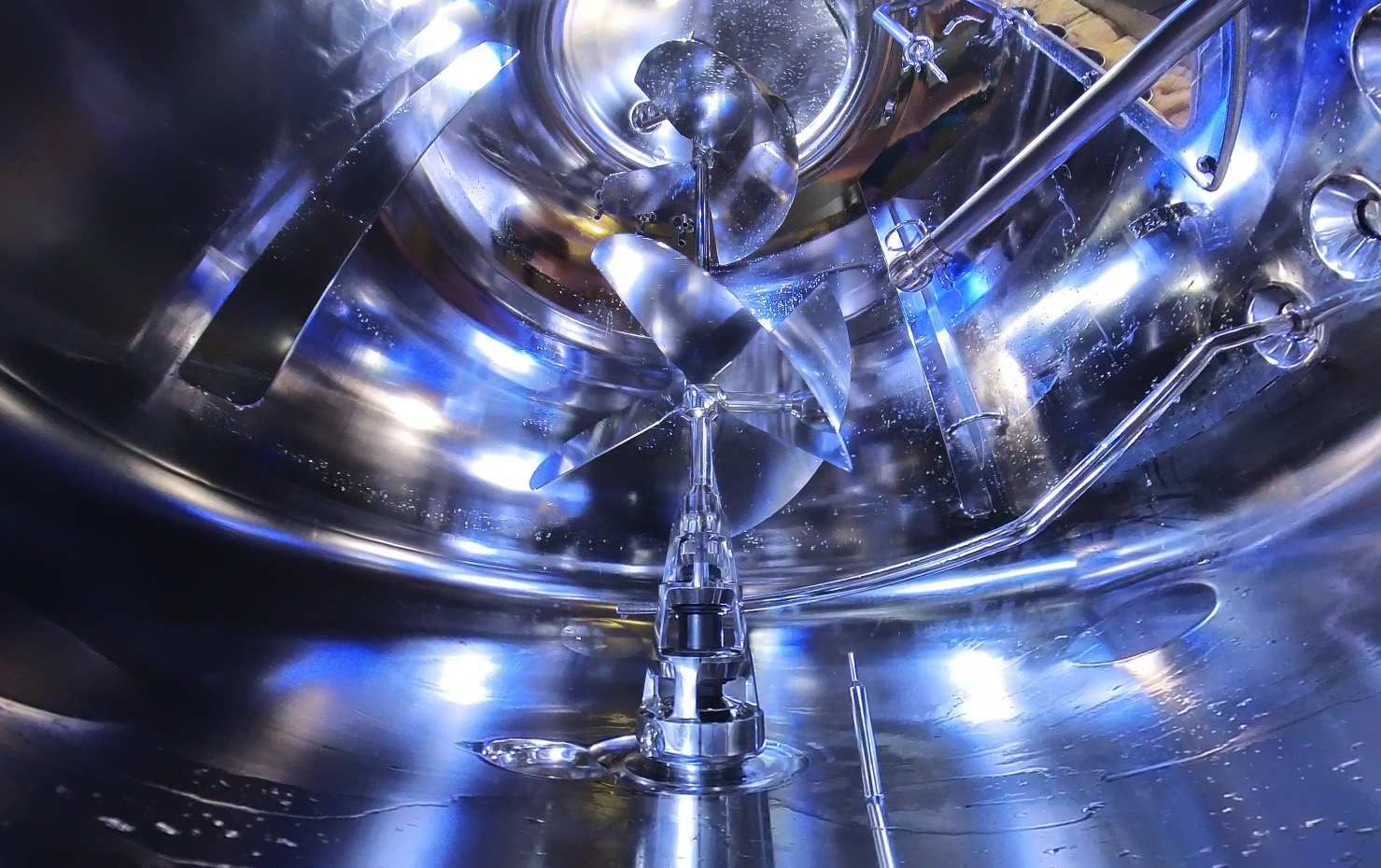

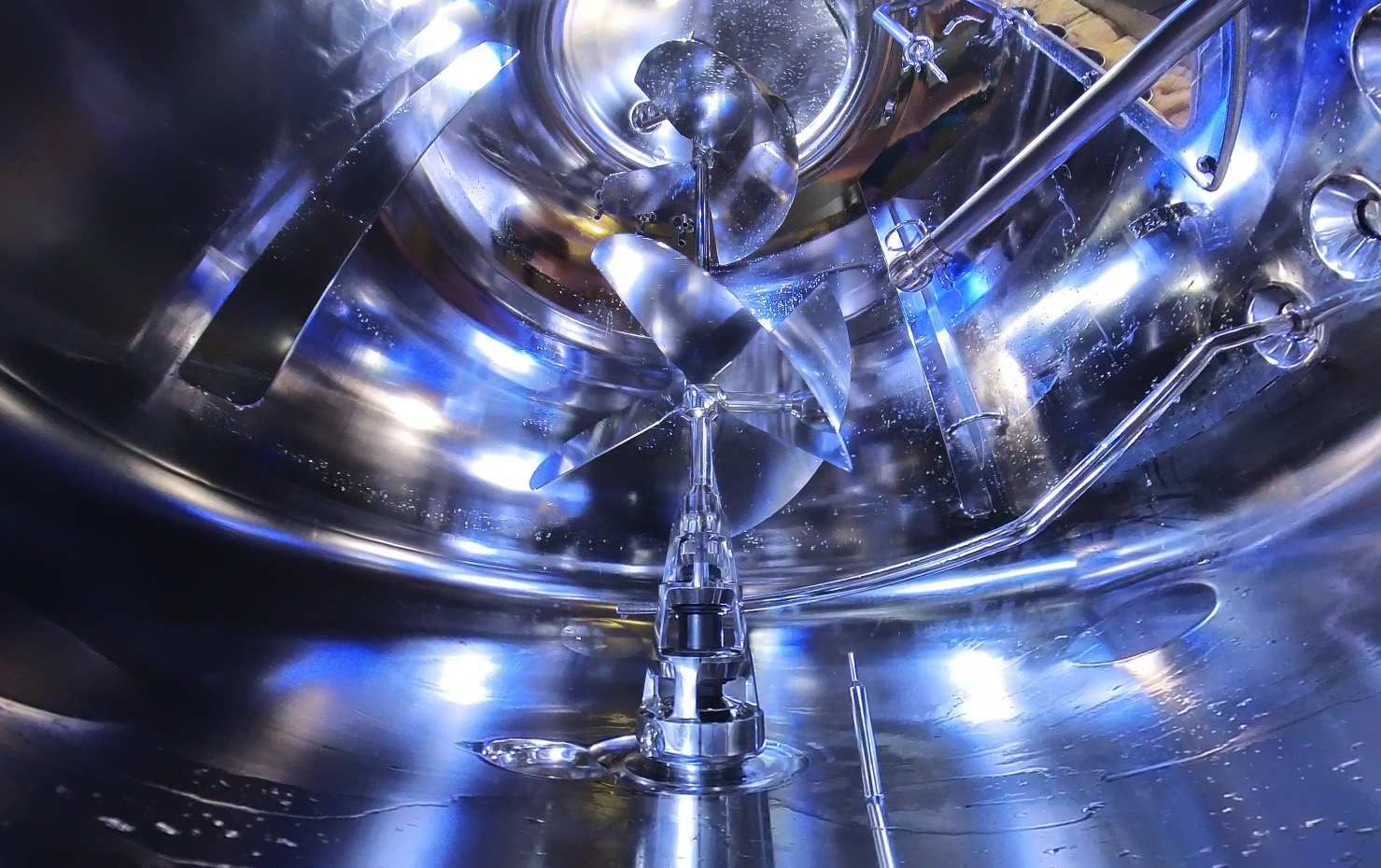

Bioreactor mixing

The task of a mixer in a bioreactor is to dissolve oxygen, get rid of carbon dioxide to ensure correct pH-levels, and also evenly distribute nutrients, waste, and heat, without damaging the cells. Since some cell cultures are sensitive to shear stress, the choice of mixer is crucial to achieve sufficient mixing, whilst ensuring cell integrity to achieve the maximum yield.

Bioreactors have played a vital role in the emerging field of cultivated or cell-based meat production. In this process, animal muscle cells are grown in a bioreactor to produce meat products without the need for traditional livestock farming. The world is currently facing an immense challenge with increasing meat production to accommodate a growing population and with that an increasing Co2 footprint. This technology has the potential to reduce the environmental impact of meat production and address ethical concerns related to animal welfare. Bioreactors might play a crucial role in the matter, and the development that comes from bioprocesses within the pharmaceutical industry will aid in the advancement of cultivated meats.

In essence, pharmaceutical bioreactors are versatile tools that are at the forefront of innovation in medicine and biotechnology. They enable the production of a wide array of biological materials and products, ranging from cells and tissues to proteins, vaccines, and even novel food sources like cultivated meat. As technology continues to advance, the capabilities of bioreactors are likely to expand, opening new avenues for scientific discovery and medical breakthroughs.

Truelev For low shear applications

Truelev For low shear applications

Truelev Mobile For shear-sensitive mixing in mobile vessels

Truelev Mobile For shear-sensitive mixing in mobile vessels

Zero-g For general mixing applications

Zero-g For general mixing applications

Zero-g Biomixer For gentle mixing in bioreactors

Zero-g Biomixer For gentle mixing in bioreactors

Zero-g Plastic For chemical applications

Zero-g Plastic For chemical applications

High Shear For emulsification and high shear applications

High Shear For emulsification and high shear applications

High Power For powder and vigorous mixing applications

High Power For powder and vigorous mixing applications

Retrofit your Mixer Replace your existing mixer with a state-of-the-art Metenova mixer.

Retrofit your Mixer Replace your existing mixer with a state-of-the-art Metenova mixer.

Truelev For low shear applications

Truelev For low shear applications

Truelev Mobile For shear-sensitive mixing in mobile vessels

Truelev Mobile For shear-sensitive mixing in mobile vessels

Zero-g For general mixing applications

Zero-g For general mixing applications

Zero-g Biomixer For gentle mixing in bioreactors

Zero-g Biomixer For gentle mixing in bioreactors

Zero-g Plastic For chemical applications

Zero-g Plastic For chemical applications

High Shear For emulsification and high shear applications

High Shear For emulsification and high shear applications

High Power For powder and vigorous mixing applications

High Power For powder and vigorous mixing applications

Retrofit your Mixer Replace your existing mixer with a state-of-the-art Metenova mixer.

Retrofit your Mixer Replace your existing mixer with a state-of-the-art Metenova mixer.